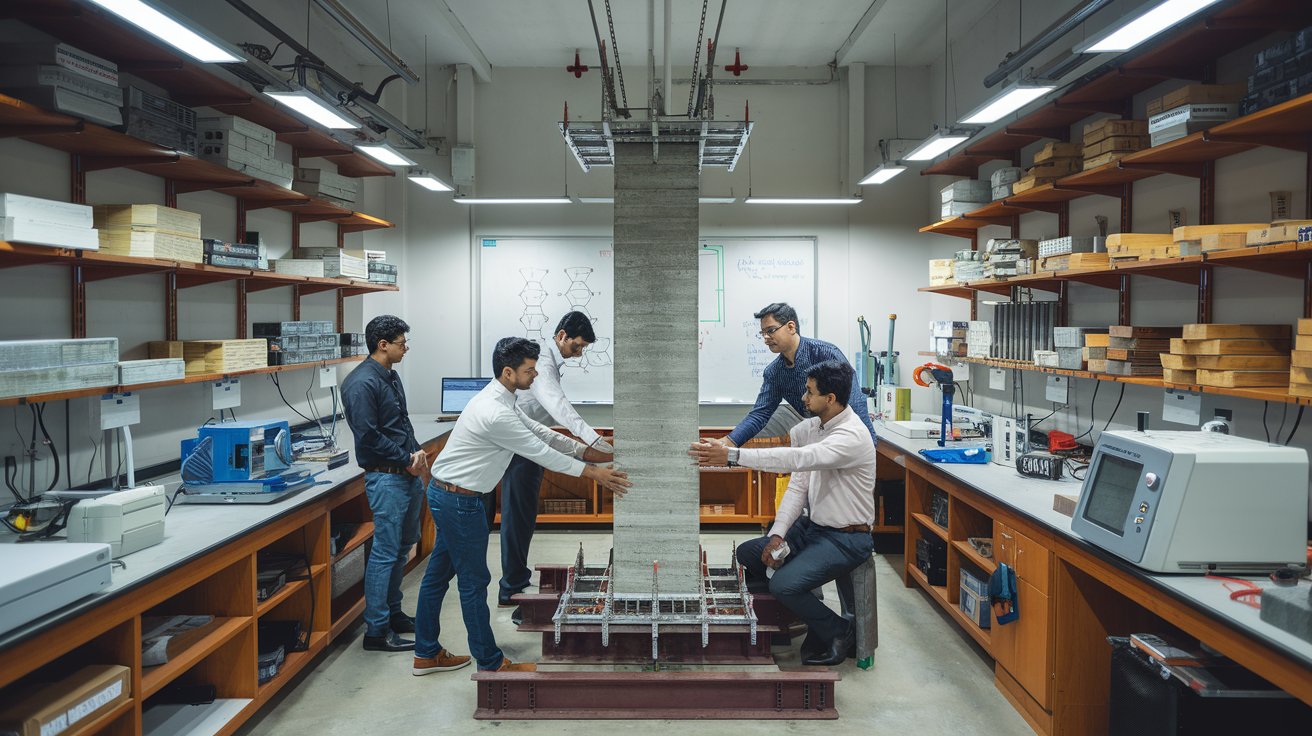

Non-destructive testing (NDT) in civil engineering is a critical process used to assess the integrity and quality of construction materials and structures without causing damage. NDT helps ensure that infrastructure such as buildings, bridges, roads, and dams remain safe, durable, and compliant with regulatory standards. At ARMM Engineering & Consultants, we specialize in offering reliable NDT services that support the safety and longevity of civil engineering projects across Odisha and India.

Importance of NDT

Civil engineering structures are subject to wear and tear over time, making it essential to assess their condition regularly to prevent costly repairs or failures. NDT techniques allow engineers to detect flaws, cracks, corrosion, and other issues in materials like concrete, steel, and asphalt without compromising the structure. This makes NDT an invaluable tool for improving safety, quality, and performance in civil engineering projects.

Key Non-Destructive Testing Methods

1.Ultrasonic Testing (UT)

Ultrasonic waves are used to detect internal flaws such as voids, cracks, or delaminations in materials like concrete and steel. It’s especially effective for testing the thickness of structural elements like beams and walls.

2.Concrete Rebound Hammer Test

This test measures the surface hardness of concrete to estimate its compressive strength. It’s widely used for assessing the condition of concrete structures without the need for core sampling.

3.Ground Penetrating Radar (GPR)

GPR uses radar pulses to scan concrete or ground surfaces and detect sub-surface anomalies such as rebar positioning, voids, and cracks.

4.Magnetic Particle Testing (MT)

Primarily used for inspecting ferromagnetic materials like steel, this method reveals surface and near-surface defects through the application of magnetic particles, which accumulate at flaws.

5.Radiographic Testing (RT)

X-rays or gamma rays are used to inspect the internal structure of concrete or steel structures. It’s highly effective in detecting hidden flaws like voids, cracks, or weld defects.

6.Dye Penetrant Testing (PT)

A dye is applied to the surface of materials to reveal surface cracks or defects under UV light. This method is commonly used for inspecting metal welds and concrete surfaces.

7.Acoustic Emission Testing (AE)

This technique listens for the sounds of crack formation or growth under stress. It is useful for monitoring the condition of aging structures and detecting early signs of potential failure.

Benefits of NDT

- Improved Safety: Regular NDT inspections help detect potential failures early, reducing the risk of accidents and structural collapses.

- Cost Savings: By identifying issues before they become critical, NDT can help avoid expensive repairs or replacements down the line.

- Minimal Disruption: NDT is conducted without causing any damage or disruption to the structure, allowing the ongoing use of the facility or road.

- Accurate Assessments: NDT provides accurate, real-time data, allowing engineers to make informed decisions about repairs or maintenance.

- Regulatory Compliance: NDT ensures that your civil engineering projects meet local and international safety and quality standards, avoiding penalties and project delays.

Why Choose ARMM Engineering & Consultants for NDT?

At ARMM Engineering & Consultants, we offer advanced NDT services backed by years of expertise and the latest technology. Our skilled team is experienced in applying a variety of NDT methods to assess concrete, steel, and other materials used in civil engineering. We ensure that your structures are safe, reliable, and long-lasting by identifying and addressing potential issues before they become critical.

Our NDT Process at ARMM Engineering & Consultants

1.Consultation & Assessment

We begin with an in-depth consultation to understand your project’s needs and identify the areas requiring NDT.

2.Site Inspection & Planning

Our team plans the NDT process and selects the most suitable methods based on the material, structure, and project requirements.

3.Data Collection & Analysis

Using state-of-the-art equipment, we perform the NDT on-site, collecting precise data to assess the condition of the materials and structures.

4.Reporting & Recommendations

We provide a detailed report of our findings, including any potential issues and recommendations for repairs or maintenance.

Ready to Ensure the Integrity of Your Structures?

Non-destructive testing is an essential service for ensuring the long-term safety and performance of civil engineering projects. ARMM Engineering & Consultants provides reliable NDT solutions to help you assess, maintain, and enhance the integrity of your infrastructure. Contact us today for expert NDT services across Odisha and India.